By Samuel Okello

A well-maintained brake system is crucial for the safety of both drivers and passengers. The brake system consists of several components that work together to slow down or stop your vehicle. In this week’s article, we will delve into the intricacies of the brake system, discuss common signs of brake issues, and provide a somewhat comprehensive guide that technicians implement to maintain and replace brake pads and rotors.

Brake System Components:

The brake system comprises various components, each playing a crucial role in ensuring effective braking:

- Brake Pads: These are the friction materials that press against the brake rotors to create the friction necessary to slow down or stop the vehicle.

- Brake Rotors (Discs): The rotors are the flat, circular discs that the brake pads clamp onto when the brake pedal is depressed. They dissipate the heat generated during braking.

- Brake Calipers: Calipers house the brake pistons and are responsible for squeezing the brake pads against the rotors. High grade cars also have calipers housing the brake pads. They play a key role in controlling the braking force.

- Brake Lines and Hoses: These are responsible for transporting brake fluid from the master cylinder to the calipers. Any leaks or damage can compromise braking performance.

- Master Cylinder: The master cylinder generates hydraulic pressure in response to the driver's pedal input. This pressure is transmitted through the brake fluid to the calipers, causing the pads to squeeze the rotors.

- Brake Fluid: Brake fluid is a hydraulic fluid that transfers the force from the master cylinder to the brake calipers. It also helps dissipate heat and prevents corrosion within the system.

Signs of Brake Issues:

Recognizing signs of brake problems is crucial for timely maintenance. Look out for the following indicators:

- Squeaking or Squealing Noises: High-pitched noises when applying the brakes can indicate worn brake pads or poor-quality brake lining material. A scratching or grinding metal-on-metal sound suggests immediate attention is needed.

- Vibration or Pulsation: A vibrating brake pedal can be a sign of warped brake rotors. This can lead to an uneven braking experience and premature uneven wear of brake pads.

- Soft Brake Pedal: If the brake pedal feels mushy or sinks to the floor, there might be air or moisture in the brake lines, or a potential issue with the master cylinder.

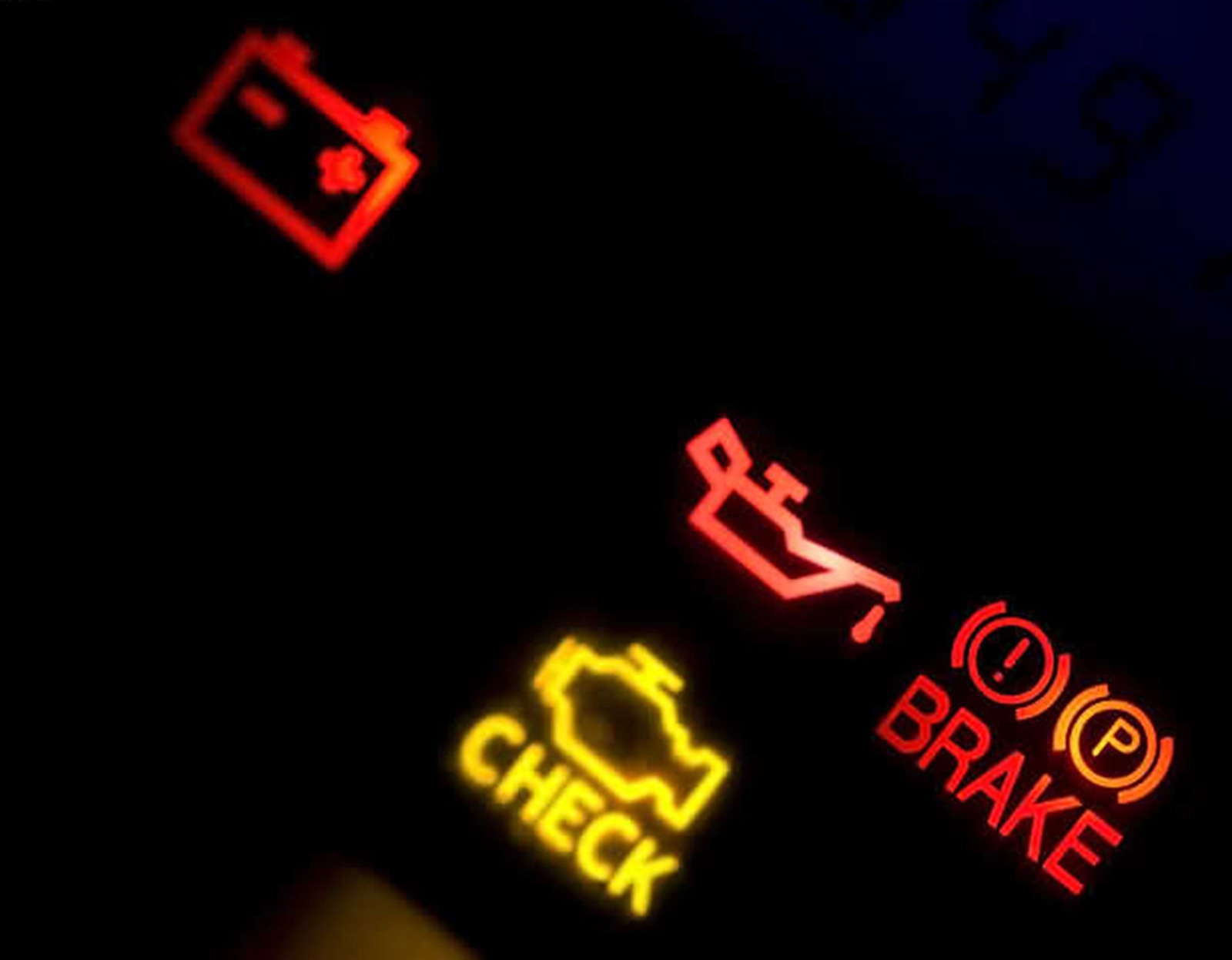

- Brake Warning Light: If the brake warning light of any form illuminates on your dashboard, it's a clear signal to have your brake system inspected.

Brake Pad and Rotor Maintenance:

Routine maintenance can extend the lifespan of your brake pads and rotors. Maintaining your brake pads and rotors is not just about preventing a sudden breakdown; it's about ensuring your safety on the road. Worn-out brake pads and damaged rotors can compromise your vehicle's ability to stop effectively, leading to potential accidents. Moreover, addressing brake issues early can save you from more extensive and expensive repairs down the line.

Routine maintenance can extend the lifespan of your brake pads and rotors. It is therefore advisable as a driver, that you pay attention to the following items.

- Cleanliness: Keep the area around your brake system clean to prevent debris from interfering with the braking components.

- Brake Fluid: Regularly check the brake fluid level and quality. If the fluid is dark or contaminated, it's advisable to have it flushed and replaced.

- Smooth Driving: Avoid sudden and aggressive braking whenever possible. Smooth driving reduces the wear and tear on your brake components.

DIY Brake Pad and Rotor Replacement:

Replacing brake pads and rotors is a moderately advanced DIY task. Here's a general outline of the process:

Tools Needed:

- Jack and jack stands.

- Lug wrench

- C-clamp or brake caliper tool

- Socket set

- Brake cleaner

- New brake pads and rotors

- Brake grease

- Bungee cord or wire (to support the caliper)

Steps:

- Preparation:

- Park your vehicle on a flat surface and engage the parking brake. Add wheel chokes to avoid the car rolling forward or backward when jacking.

- Loosen the lug nuts on the wheel but don't remove them yet.

- Lifting the Vehicle:

- Safely lift the vehicle using a jack and secure it with jack stands.

- Remove the lug nuts and the wheel to access the brake assembly.

- Removing the Caliper:

- Locate the caliper (it's usually held by two bolts).

- Remove the caliper bolts and gently suspend the caliper using a bungee cord or wire. Do not let it hang by the brake line.

- Removing Old Brake Pads:

- Slide out the old brake pads from the caliper bracket.

- Compressing the Caliper Piston:

- Use a C-clamp or brake caliper tool to compress the caliper piston fully into the caliper housing. This provides room for the new, thicker brake pads.

- Installing New Brake Pads:

- Apply a thin layer of brake grease to the back of the new brake pads.

- Place the new pads into the caliper bracket.

- Inspecting and Replacing Rotors (if necessary):

- If your rotors are worn, damaged, or warped, it's recommended to replace them.

- Remove the old rotor by unbolting it from the hub.

- Reassembling:

- Put the new rotor in place if needed.

- Slide the caliper back over the new brake pads and secure it with the caliper bolts.

- Final Steps:

- Put the wheel back on and tighten the lug nuts in a star pattern.

- Lower the vehicle, and once on the ground, fully tighten the lug nuts.

Conclusion:

Maintaining and replacing brake pads and rotors is not only a matter of vehicle maintenance but a crucial aspect of road safety. Regular inspections and timely replacements ensure that your braking system operates optimally, keeping you and others safe on the road. If you're comfortable with intermediate-level DIY tasks, you can tackle brake pad and rotor replacement yourself. However, if you're uncertain or uncomfortable with any step, it's best to seek professional assistance to ensure the job is done correctly and safely.

SAMUEL OKELLO

B.Eng. Automotive and Power Engineering

Technical Director

S-Line Motors LTD

Plot 6, Ojara Close, Mbuya

https://goo.gl/maps/bEGeVEN7tUVTqHnu8

0779745722 / 0708000888