Minister Anite says vaccine, test kit manufacturing facility will save Uganda over shs170bn

The State Minister for Trade and Investment, Evelyn Anite has said the Vaccine Access Initiative (VAI), a private-public partnership, which aims at manufacturing vaccines, test kits and drugs will save the country a huge sum of money that was previously being spent to import the same.

“Our president is emphasizing the growth of the pathogenic economy and this facility is walking the talk to make sure we have the vaccines manufactured here and the testing kits. If we didn’t have it here, we would be donating 46million dollars(approximately shs174billion) per year in acquiring test kits for malaria, TB, HIV and many others,” Anite said.

Keep Reading

- > Parliament questions government's Shs1.1 trillion supplementary budget

- > Salam TV elevates coverage of 11th international Quran competition 2024 in Rwanda

- > Electoral Commission budget expected to rise

- > PPDA asks districts to use use alternative procurement processes to avoid returning money to consolidated fund

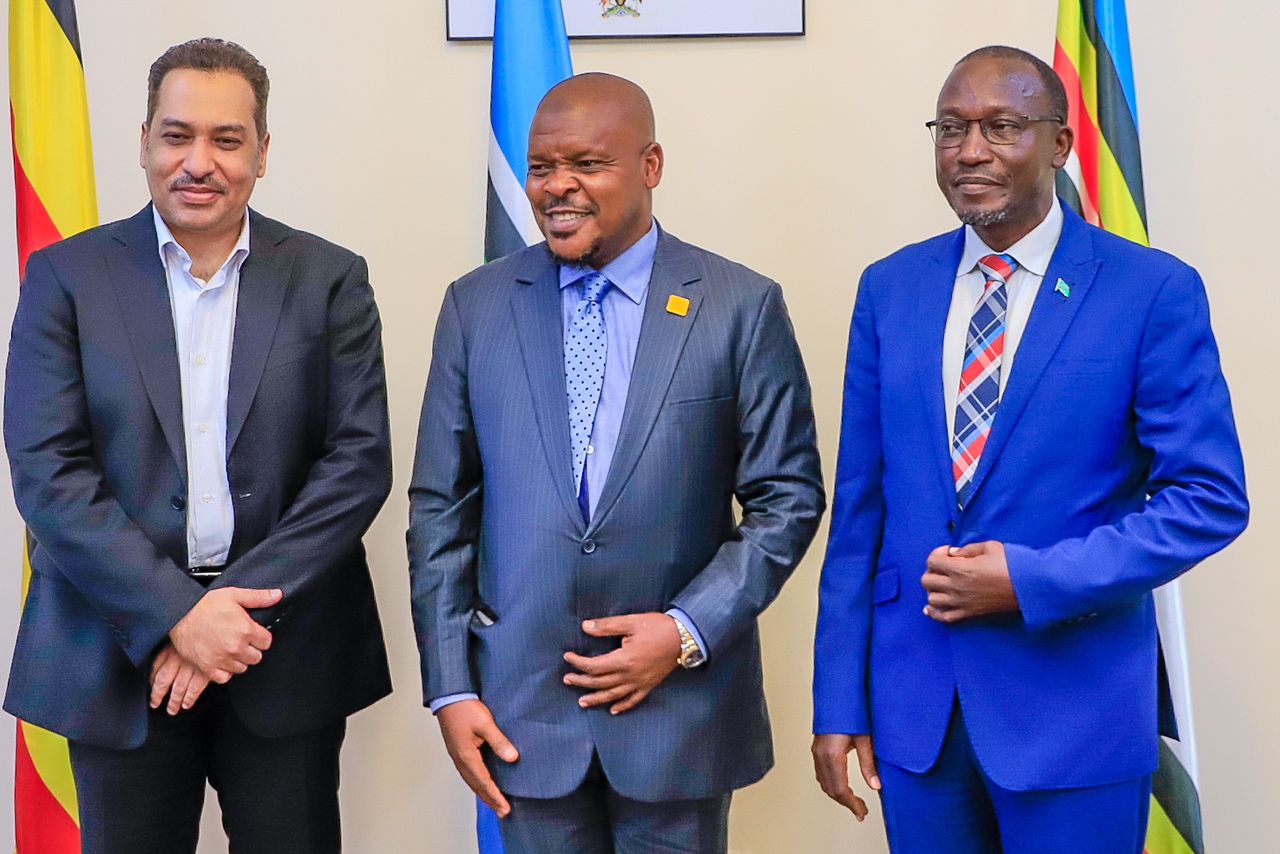

The minister was on Thursday inspecting the ongoing construction works for the Vaccine Access Initiative (VAI) in Ntinda.

Anite explained that previously, Uganda has been spending a lot of money to buy the products that will be produced at the facility, noting that manufacturing them locally will be a proper upgrade for the country.

“This is making Uganda proud and we shall save a lot of money. We shall be getting the products here and on international standards. I am seeing employment already happening, knowledge transfer happening and it is good news for us. This shows Uganda can manufacture the products we thought we could not.”

Anite said government is ready to offer all the necessary support to the investor to ensure the facility realizes its potential .

She mentioned a number of incentives that government is ready to offer the facility.

The facility

The Vaccine Access Initiative (VAI) is a private-public partnership formed by the Ministry of Health and two private companies Microhaem, a local firm, and America’s Imagine pharmaceuticals. .

According to Cedric Akwesigye, the head of VAI, the project started in 2021 and by January next year, they expect to start manufacturing.

“We intend to manufacture 12 products in three lines of production including test kits, drugs and vaccines. By January one of those lines should be ready to produce. By the end of next month, the contractor will be giving us the factory and for three months we shall be carrying out tests .We shall keep producing, test and pour until we meet the required standard for product us,” Akwesigye said.

He noted that at full capacity, the facility will employ more than 200 people with 150 employed in the packaging of the products whereas 50 will be experts and the other members of the technical team.

“The production will be fully automated to meet WHO standards and ensure products are purchased and taken to other countries around the continent.”